Shenzhen Xingsheng Pearl Chemical Pignent .Co., Ltd.

Contact: Mr. Zhang

Phone: 86 0755 29497723

Mobile: 18588878083

Fax: 86 0755 32998090

Email :info@xs-color. com

Address: Lougang South Industrial Zone, Songgang Street, Baoan District, Shenzhen

Website: www.xs-color.com

Website : en.xs-color.com

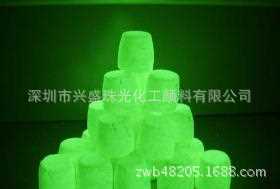

| Place of origin | Shenzhen | Whether to import | no | kind | Color luminous powder |

| Field of application | ceramics | Effective | Long-lasting | Model / Specification | 5kg/bag |

| Brand | Prosperous | colour | Yellow green | Scope of use | Decorative paints for plastics |

| special service | Free sample | product name | Luminous powder | Whether dangerous chemicals | no |

| use | For coatings, plastics, ceramics |

In the injection molding, the long-lasting luminous powder is mainly caused by the hardening of the luminous powder and the blackening of the screw. How to avoid this phenomenon?

1. First of all, the choice of luminous powder should be as fine as possible, the soft powder of luminous powder.

2. Secondly, the selection of the machine should be as old as possible, and the shorter screw injection molding machine (generally recommended to be within 0.8 meters) to produce luminous products will be better.

3. Try to mix the mixture as much as possible to avoid mixing the machine.

4. In addition, the temperature and pressure should be reduced as much as possible during the injection molding process, and the temperature and pressure should be lowered as much as possible on the basis of the finished product.

5. The proportion of luminous powder used for post-injection molding is generally 3%-10%. The ratio can be adjusted according to the requirements of luminous brightness and cost accounting, but the better addition ratio should not exceed 10%.

The luminous powder produced by our company has softer powder, faster light absorption, finer particle size and high brightness. It is good for the blackening phenomenon of luminous powder in the injection molding process from the luminous powder.